our story

after tinkering around in woodworking in the early 2000s, making birdhouses, puzzles, and holiday ornaments for fun, peter beebe created a few plain wooden cutting boards. still very new to the craft, his pieces were nothing like b&b woodworks’ are today. after a trusted friend of peter’s son jim complimented the boards but suggested that the boards should incorporate a “cape cod theme”, jim took that idea and ran with it. at this point, the beebes moved from a small cellar hobby into jim’s recently transformed garage, where b & b woodworks would soon call home. in its infancy, the business had few product ideas and minimal equipment, but held on tight to an idea of cape cod themed kitchenware. after some time, their products began to be noticed for their craftsmanship and uniqueness and were sold in local stores. though their cutting boards, cheese boards, and coasters reflect their origin and are still very popular to this day, they have shifted some of their work to include more creative and custom products, along with their product staples.

over a decade later with hundreds of products created and sold, jim and peter continue to create in their local woodworking shop.

over a decade later with hundreds of products created and sold, jim and peter continue to create in their local woodworking shop.

our process

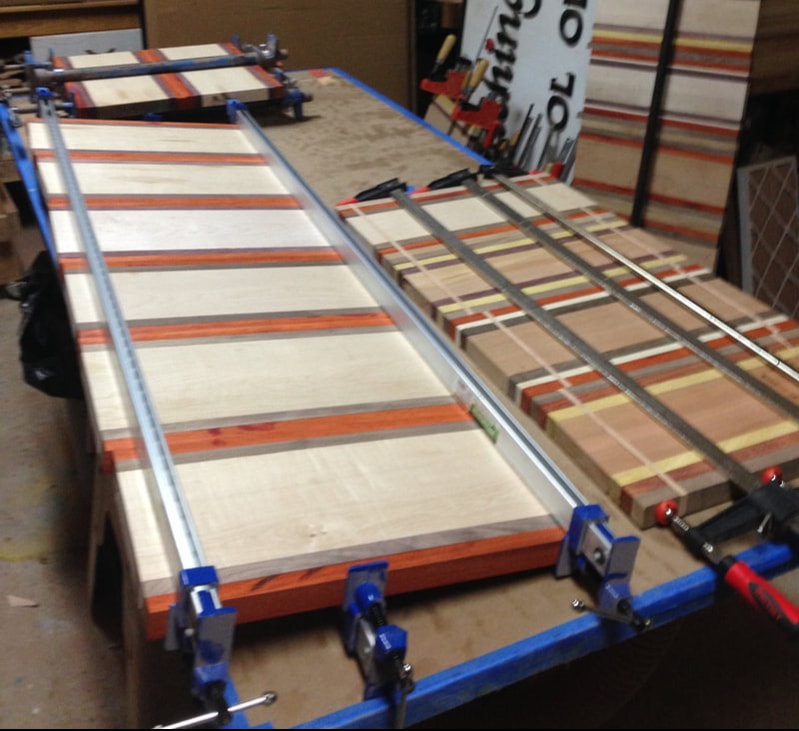

the following are b & b woodwork's basic steps in creating cutting boards. though some steps are exclusive to cutting boards, others are universal for every product.

|

first, the middle strip of wood and the strips of accent wood like the red looking padauk or violet colored purpleheart are cut and prepared the board is then trimmed, cut, and sanded lastly are the finishing touches that make the boards so high quality: routing, sanding, branding, and oiling |

next, the wood middle and accent strips are glued together and held using clamps after that, the cutout design is scribed onto the wood and cut using a scroll saw |